I like to experiment with materials, designs, and techniques outside of conventional luthiery to build low-cost, high-quality, fully-functional, and attractive electric guitars and basses. What I am not interested in is doing the same old thing the same old way it has been done for decades.

More: Home ...

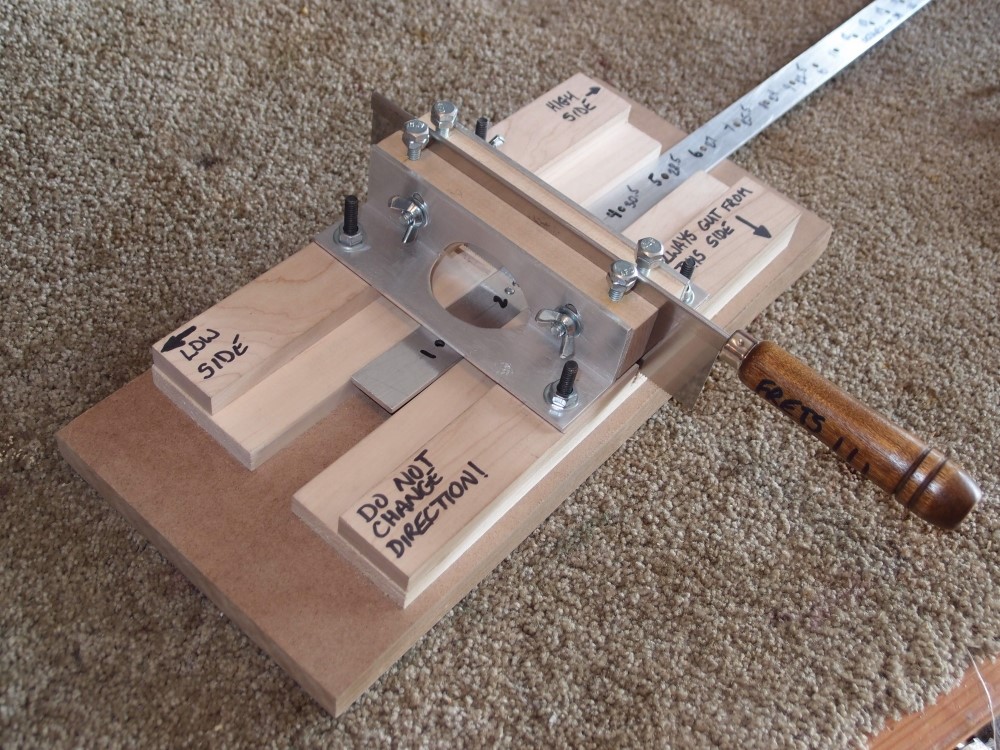

The Fret Slotting Jig is basically a very precise mitre box. What makes it a fret slotting tool is the Fret Guide, which attaches underneath the workpiece with double-sided tape, and engages a pin on the Fret Slotting Jig directly below the saw blade. The holes in the guide are spaced to Fender's formula, so depending on which hole you start with for the nut slot, you can cut anything from a 36" bass to a 20" ukelele, and all the standard scales in between. The guide fits snugly between the inner rails of the jig to keep the workpiece centered and straight.

More: Fret Slotting Jig ...

Lee Thompson:

January 23, 2024 at 1:32 PM

Enjoyed perusing the site...I have a good friend who originally apprenticed under his dad as a cabinet maker and later went back to school and got his degree in mechanical engineering. He's a really smart guy, down to earth, and sharp as a tack. You guys sound like you could be related! I have been considering building a Danelectro type guitar. I'm a lefty so my options are limited...any info about vintage sounding lipstick style pickups is appreciated. Paying for a "Booteak" pickup to duplicate a budget pickup seems like a nitwit move. Anyway, thanks for sharing your knowledge and insights. There's a lot of hogwash out there...

TatBou:

January 13, 2024 at 2:12 AM

Man I love what your doing and how your doing it, keep up the great work!

P.S.

My favorite builds the upright audiovox

John Paxton:

November 25, 2022 at 4:41 AM

Hi

I have found your website - and your approach to building guitars and your techniques utterly inspirational.

I build electric lap steel guitars, mainly from recycled, reclaimed and re-used materials, searching skips and freebie bins in DIY stores - looting anything which might be useful.

I have a new website - still under construction https://sites.google.com/view/paxtonelapsteelguitars/home?authuser=0 . Thanks to your passion for Audiovox, I have just built a replica 436 lap steel - from a mahogany window sill. Beautiful shape.

I'm thinking of building a DanElectro style - hollow-body masonite, not the solid body they made - lap steel. Could be interetsting!

Thanks again

Best wishes

John Paxton

Tasburgh, Norfolk UK

Alan Herbst:

July 15, 2022 at 8:46 PM

Hi! Stumbled in here by accident and I am TOTALLY hooked!

Have you ever done anything with a Les Paul carved top style body in a short scale bass?

Due to arthritis I am now playing short basses. I spoiled myself with neck through basses for 40 years and now I find no one makes them short (for a reasonable price) so I am on a quest to create my own, eventually. I'm gonna start with modifying random guitars like you have.

Peace!

Alan

Bob Yost:

July 8, 2022 at 11:51 AM

Wonderful Amazing Work! ThankU

May I ask how about

Have you ever made a 3-string? Bass

Me Silly’

Bob

Harri H.:

June 16, 2022 at 3:10 PM

Hello! Great content in these corners of internet. I find myself coming back here quite often lately. I read your stuff with great interest. I like your sense of humour very much also!

I have 4 Korean Made Danelectros and they need some care. I just started the process of straightening those bridges. I'm going to add one more screw in the middle for support that plate. You wrote somewhere that the old ones don't warp. Well, I guess it's like with everything: you get less and less for your money, even if it seems otherwise.

Greetings from, at the moment, sunny Finland. HH.

Ed Malison:

March 25, 2022 at 8:30 PM

I like your website. I see innovation all over.

luthierylabs.com:

September 24, 2020 at 7:59 PM

Like this site? Hate it? Or just say Hello.