Kubicki Factor Bass (1/13)

Sort of like a Kubicki, but not really.

Back in the glorious 80s, Kramer tried to cash in on the headless craze with a widely unpopular model called "The Duke":

Apparently, it started out as an 8-string that went bad. One of the workers sawed off the body wings and headstock, and "The Duke" was born. There was also a guitar version. "The Duke" incorporated all of the worst aspects of a Steinberger, and none of the good, like the super-precise tuning. However, it is an interesting idea that could be done much better.

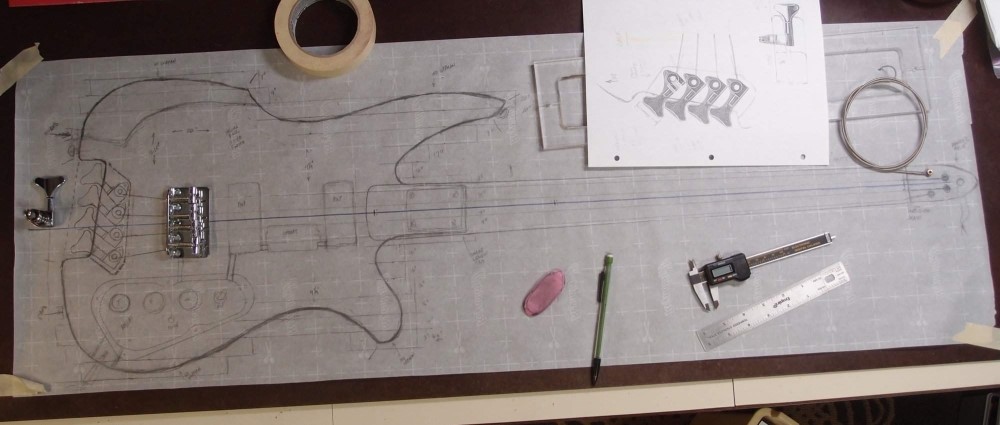

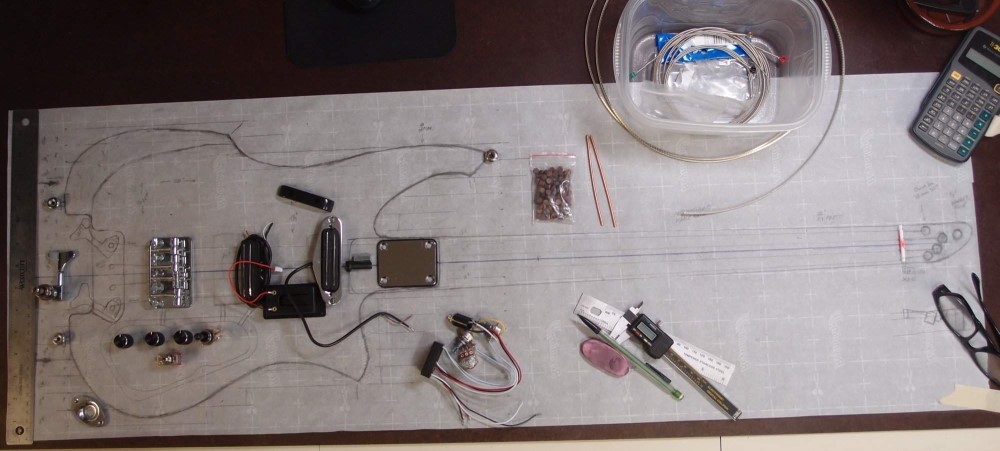

Note the real bass tuners, with much less string fan-out than the Kramer, despite the fact that Kramer used much smaller guitar tuners. I scanned four copies of a spare machine from the parts box, and fooled around with them until I got it as tight as possible. The tuner spacing is ~24mm; the bridge is 19mm, so the outer ones are about 8 degrees off-angle. Why Kramer couldn't do this is a mystery to me.

Questions or Inquiries?

Just want to say Hello? Sign the .