Kubicki Factor Bass (3/13)

Dec 16, 2017

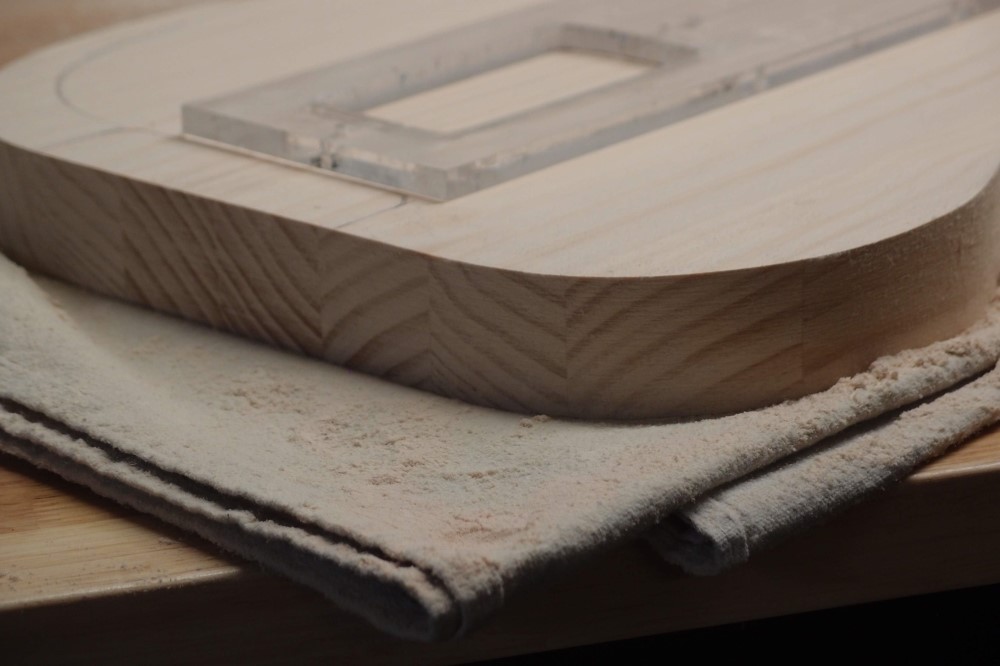

After staring at it for few days and adjusting the contours, I finally committed to the bandsaw. Here you can see the outlines which have then been shaped on the oscillating belt sander. The final contours are slimmer and swoopier than my initial essay. I'm not trying to do an accurate outline as with the Eagle bass, I just want the overall look.

After the outer edges were settled, I went back to block-sanding the faces until all the crookedness was removed - they are now as flat as I can tell. Cutting the outline reduced the apparent cup immediately, as I predicted, since the straight edge has less to span. There is no noticeable difference in thickness.

While sanding, I preserved my drawn marks with a Sharpie, which will go away when the edges are rounded-over. There is also a chamfer from the tuners up to the upper corner and a relief on the back. These are very pronounced on a Kubicki, mine will be smaller to fit my modified design. For the rest of the body edges I will do a standard 3/8" roundover.

Real Kubicki has a very deeply inset bolt-on neck; mine will be a standard Fender-style mount. I have never been bothered by the presence of a heel under the neck. What are you doing way up there anyway? If you want to make squeaking sounds, play guitar.

I deliberately left the area inside the horns to support the router template. After the neck pocket is done, I will take away that wood. I also left the cutout for the tuners at the back until after I was done block sanding, otherwise, the sanding might have come out uneven.

Here is a shot of the end grain of the glued-up pieces. Like it or hate it. The belt sander is not perfectly perpendicular, so the seams at the more inclined curves came out crooked. This is easy to fix by simply flipping the piece over and gently re-sanding until the seams become straight. Notice the Radiata pine has no black pitch marks, and you won't find even a tiny knot on the whole piece.

The wood cut with no problems. I had to use a fresh belt on the sander, the extra hardness over Alder or Poplar is apparent. The faces took very few dings or tool marks, and only slight ones that will probably pop back out with hot water. This is a very nice wood to work with. The glue lines on the faces are almost invisible.

I have decided not to do the drop tuner. For the 32" scale, the D would be at 36". With some careful planning, that should be within range of a standard long-scale string set. The mechanism could be designed around a clothespin spring and a bolt. The lever could be made from aluminum stock. It could probably even be made to look halfway decent. I think it could be done, I just don't feel like doing it, and I don't think I'd use it much. Since the design has a proper bolt-on neck attachment, I could always do it in the future on a new neck.

Dec 17, 2017

Here is the Kubicki neck pocket all done. My new old router performed flawlessly. Behind, you can see another body set up to be routed. Note how the template is supported all the way around by double-sided tape. You can also see the walls remaining on the Kubicki for the same purpose. Those will be removed next. It's not a bad idea to make the neck pocket your very first cut on the wood.

And here are both neck pockets all finished. Standard Fender neck pocket depth is 5/8", or 20/32" on my little ruler. I made these 1/16" shallower, because of the slightly thinner body. This is well within the adjustability of a Fender bridge. On a thin-bodied Mustang, the pocket is noticeably shallower and the bridge taller to allow for it.

I enlarged the hole in the router base to almost 2" so I can better see what I am doing. The bit setup is a 1/2" x 1/2" hinge mortising bit with 3x 1/2" bearings stacked under a retaining collar. The bit was actually in the router when I received it. I'm sure if the seller had the wrench to remove it, he would have, so lucky me. It is the perfect bit for this sort of thing, extra long shank, and came with a bearing and collar.

Normally, it is easier to hog out as much wood as possible with a Forstner bit on a drill press, and then finish the job with the router, but I wanted to give the new router a good workout. It takes 3-4 cutting passes to make the depth, and then one very thin pass to clean up the bottom. On the second body, you can see there is no place to work in from the side. Instead, just plunge the bit into the wood away from the edges, gently with a slight whirling motion, you don't need a plunge base.

This little router is perfect for this sort of work. It just feels much more controllable than the big one, even with just one hand. With this extra-large base, it is very solid, and the cuts come out perfect without the nervousness that always accompanies the big router. There are several small routers like this on the market, often called 'laminate trimmers'. The Bosch Colt is the classic, but this DeWalt is better in every way. These little routers only take 1/4" shank router bits, which is not a problem, long ago I decided to standardize on that size.

The Radiata routs beautifully, you couldn't ask for a better wood. Now it is back to the bandsaw and belt sander to finish the contours.

I did some searching, and this is not the first time Radiata has been used for a guitar body, but it is the first time it has come from Home Depot. Mostly what I found was a lot of clearly uninformed opinions of people who seem to think all pine is white pine. Another camp says you should only use white pine because Leo did. A group in Australia talks about Radiata being soft, knotty, and crooked, I'm not sure what they are talking about. None of these people actually seem to know anything about wood, although there is a great deal of expertise on tonewood.

All I know is results. These two bodies are pretty much flawless. The glue joints are almost invisible, the grain is attractive if a bit linear. If I did a good job with the glue-up, these laminated bodies will be much more stable than a one or two-piece body. This wood is nicely hard, medium weight, and has no vices in cutting, sanding, or routing.

Both these bodies are about 4.1 pounds right now. If they were basswood, they would be 3.3 pounds, Alder 3.6 pounds, Poplar 3.7 pounds, Ash 4.4 pounds.