Kubicki Factor Guitar (1/8)

I was so pleased with the bass that I thought I'd try a guitar. This is a little more complicated, as there are six tuners rather than four, but it worked out well. The battery is for an Artec tone control that I wanted to try. More later ...

Nov 15, 2018

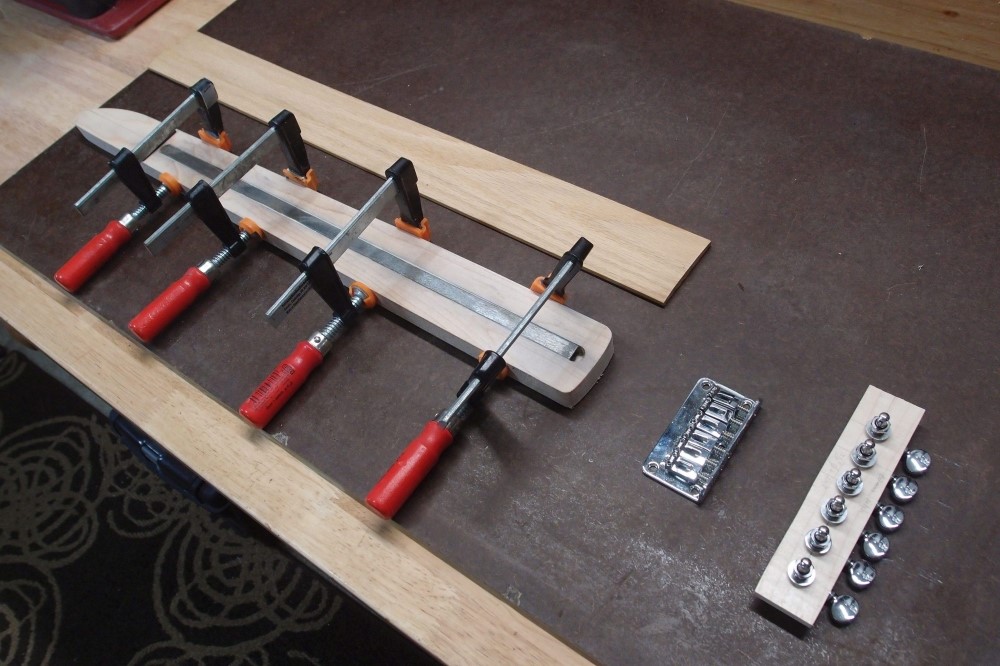

Quickly roughing-out a guitar neck. The truss rod is a 1/2" square steel tube. This is a bit heavy, but extremely strong, and results in a neck that will stay arrow-straight forever, and never need adjusting. The steel is roughed-up and set in the slot with wood glue. It is necessary to clamp the piece at this point because otherwise the moisture in the glue will swell the wood and make it crooked.

The air space inside the tube resonates for extra tone. Sure it does.

How's that for a fast job?

Nov 16, 2018

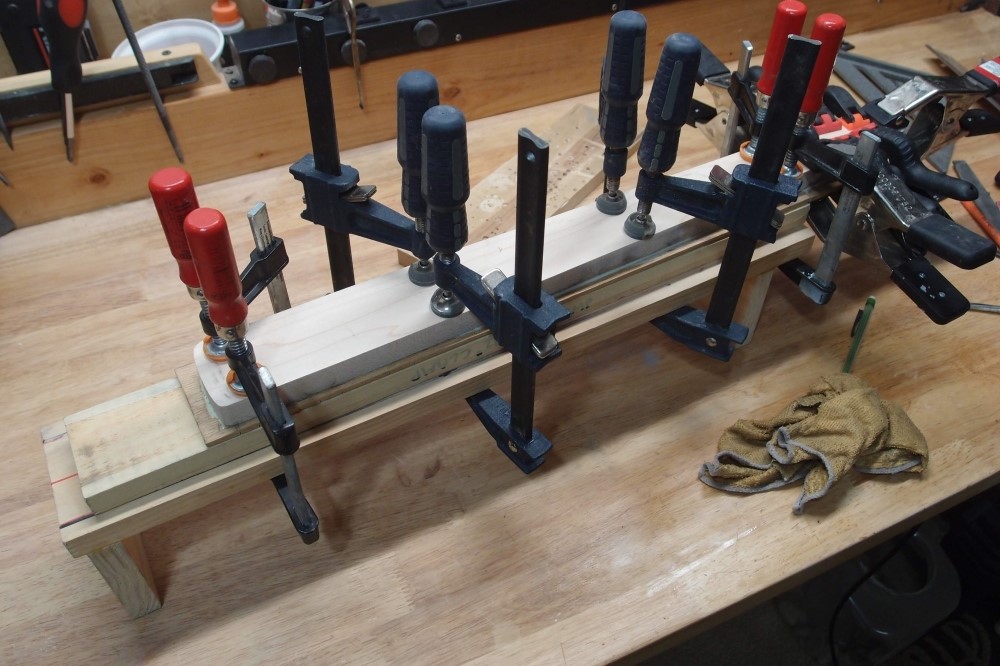

Still proving concept: I sawed off the excess fretboard, then belt-sanded it almost in to the maple. Then I finished the job by block sanding with half-sheets of 80. I was smart this time, and drew all my layout lines about a mm outside of where I wanted, so when I did my rough shaping, I could come in to the line and still have 1 mm for finishing. Because if I see a line, I just can't stay away from it, I'm like a dog or something.

Interesting note: the tannins in the oak turned the glue black.

Everything is now perfectly smooth and straight. The neck is a little wide at the nut, so that the nut will fit inside the binding without trimming it. This will give me a little extra width to fit the string retainers, all six of them. I also lightly re-sanded the radius, and flattened the headstock, otherwise, the 6mm binding will not quite cover it. I'm tired, I don't want to do the binding slot tonight, but that will be done the same way I did the Factor bass. The method from a few posts ago won't work here, as the binding will go all the way around the end. The two ends will join at the heel. Acetone will melt them together seamlessly.

I think oak against maple looks lousy, but a strip of binding separating them looks sharp. It also helps with the table-leg look that you get with oak. In coming years, you're going to see the big names turn to oak more and more as their old standbys get outlawed by the gubment.

A stray thought: those hanging files that your office is filling the dumpster with, now that we are paperless ( yeah right ) are perfect for storing and organizing sandpaper. At least until sandpaper becomes digital.

Questions or Inquiries?

Just want to say Hello? Sign the .