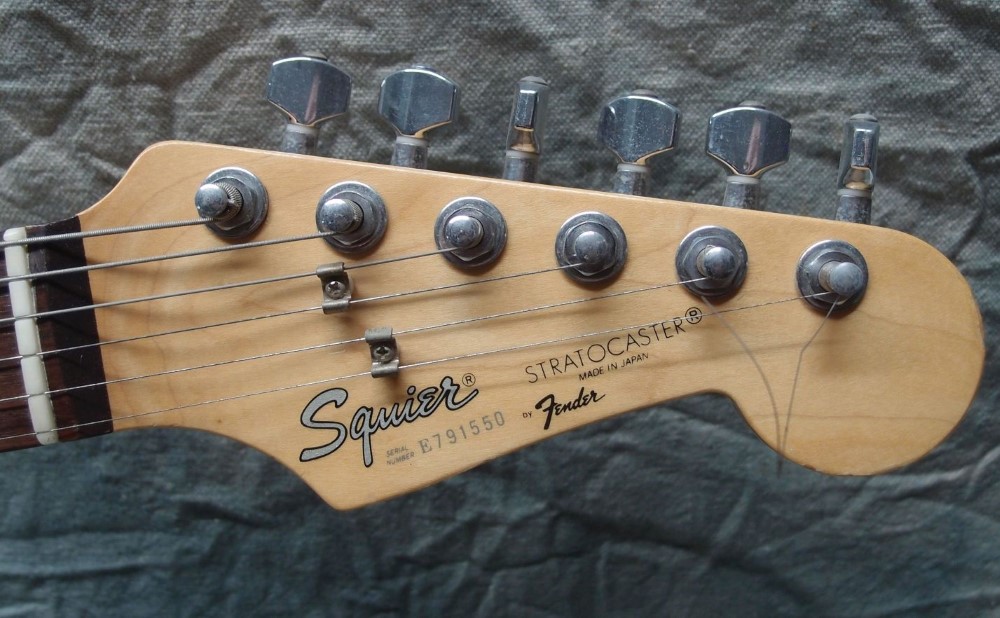

Audiovox Stratocaster-Style Guitar (1/5)

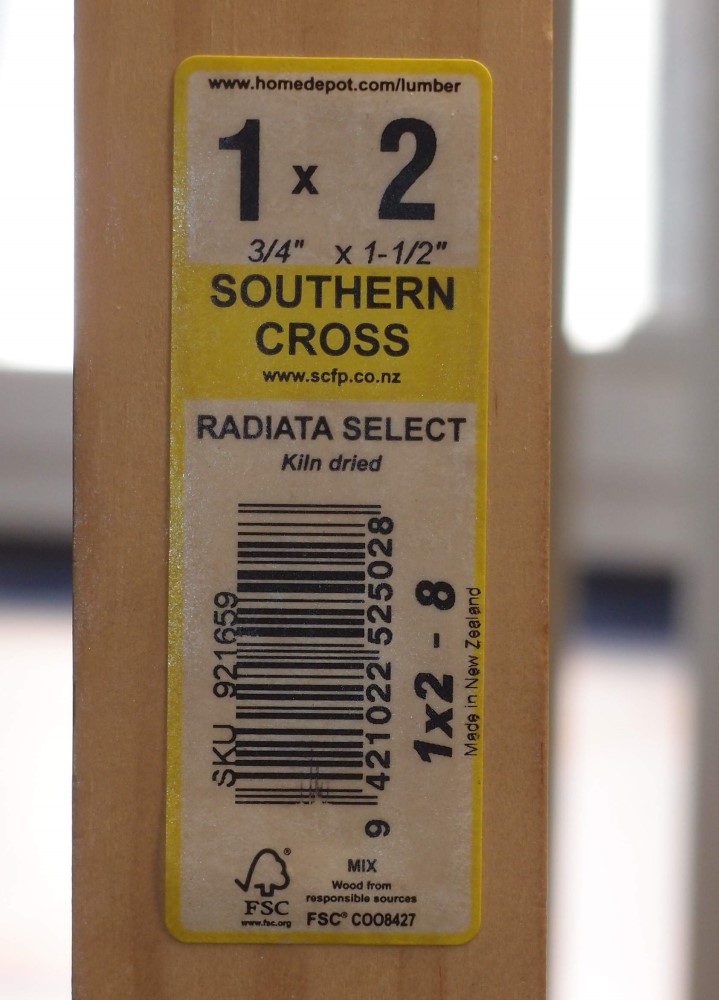

This one was a testbed for the Radiata glue-up body construction. I had lots of Strat hardware lying around from all the bass projects, so I decided to use some of it. As usual for my guitars, this has a fixed steel truss rod. This is the last of my Audiovoxes, and probably my favorite.

Questions or Inquiries?

Just want to say Hello? Sign the .