Audiovox 736 Bass (1/4)

This was my first Audiovox project. Below is the original walnut body, fairly true to the original. My goal was to build the closest possible reproduction of the original Tutmarc Audiovox with modern parts. The ergonomics were very bad, much like a Steinberger. The headstock geometry is also not great, you can see how two of the tuners are reversed to make it work. These are expensive Gotoh tuners that are tight enough to work in reverse; I wouldn't try this with Chinese cheapies.

The finish on the original body was many many coats of Danish oil, finally polished. It took a long time, and I will never repeat it. The finish on the new body is oil-based polyurethane.

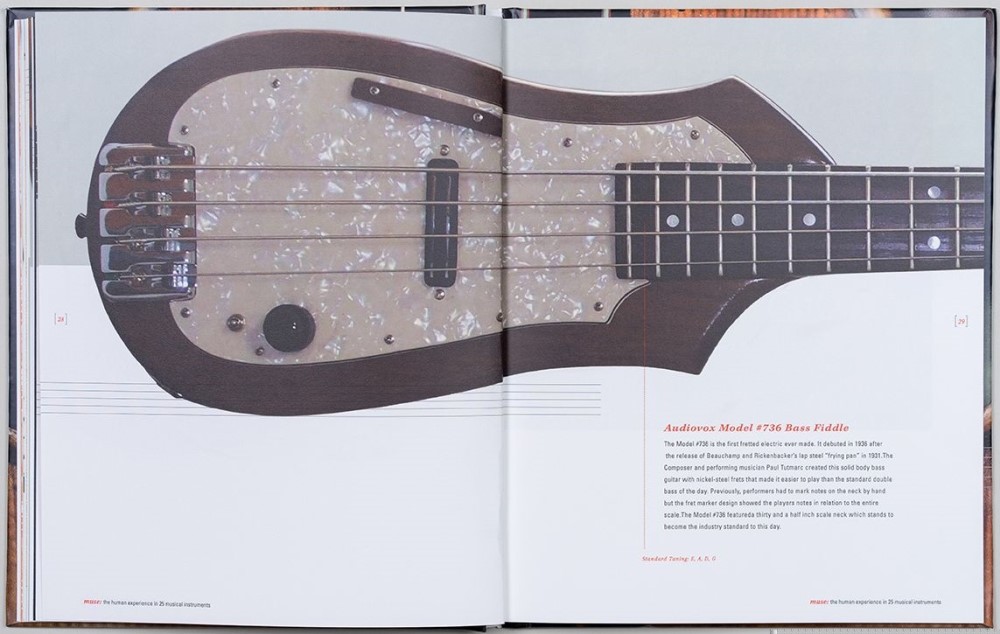

It's not like I was being completely authentic when I built this, but apparently, a few people were fooled. Here it is in a book on musical instruments, being presented as the real thing ( without my permission ! )

And here again, on a bass blog, again without permission:

Those folks will be sorry to see the image below.

I got tired of this one being unplayable, so eventually, I made a new poplar body for it, stained to resemble the original walnut. The more-authentic brass pickguard is actually clear plastic painted on the back. The neck is solid walnut with the original Danish oil finish.

The scale is 32", more or less Fender geometry. Note the unusual tuner layout, one tuner on each side is reversed to make all the string pulls work on the authentic headstock shape. All my later Audiovox builds use a revised headstock shape that is much more conventional.

The stacked knob imitates the original's one big volume knob, while adding a tone control. The tiny switch changes the pickup from series to parallel mode.

I got a lot of mileage out of all the walnut scrap from this project.

Jim Chapman:

June 14, 2020 at 11:30 PM

Very nice work. Would you ever consider building an exact copy?

alder:

June 15, 2020 at 2:38 PM

Thanks, and no. The original is not a very good design, and in any case, a barely-functional antique. My evolved version is a much better instrument.