Audiovox 736 Bass (3/4)

Apr 13, 2014

Classic Vibe Modern Player, I guess that's what it is. I had the whole thing together for a couple of days, then took it apart again for final finishing and tweaking. Other than that, the setup is coming along as expected. Always starts out awful and gets better over time as the new parts settle and you get everything dialed in. Plays pretty good already. With a new build, I usually get to a plateau pretty quickly, and then let it sit for a few months. Once everything has stabilized, I go for the final setup. My benchmark for basses is a '90s Japanese P that I have, and likewise, for six strings it is 1985 Japanese Squier Strat.

The guitar pickup works great, no issues with the width, the E and G strings catch enough magnet to sound fine. The mode switch went in after all. Series mode gives a strong Precision sound. Parallel mode is a lighter Jazz sound. Single-coil is in-between, closer to the Jazz sound, but punchier. You could omit the non-humbucking single-coil mode and not really miss anything, but I had the special switch lying around and I wanted to use it for something. It is quiet in all modes. That's pretty good for a cheap pickup that is not even supposed to be in a bass. It is also a very hot pickup - 5.5k per coil, so series mode roughly equals the impedance of a P-pickup. In nearly the same position with a similar width, it is no wonder it sounds like it does. A 683 cap lets you really dig deep with the tone control.

The ergonomics are not great. Plays a lot like a Steinberger, all the same flaws - the body is just too small. Thankfully, walnut is pretty heavy and weighs it down a bit. Takes some getting used to though. I ended up needing a shim for the neck, not the bridge as I had expected. I'll never buy another bridge like this - it is a real bother to set up, with 16 tiny set screws just waiting to get lost. You can't get at the intonation lock screws without removing the strings. Leo's bent steel bass bridge is still the best design ever.

Tuning up is interesting. Even with Tutmarc's reversed-taper headstock, I managed to give each tuner a fairly straight string pull to the nut, and at the same time maintain nice even spacing of the posts and knobs, and keep all of them clear of each other. It's a clever arrangement, but upside-down inside-out backward from anything you're used to. The plastic nut cracked, so I am going to make a brass one, and the flat headstock badly needs string hold-downs.

The first pickguard delaminated along one edge and I scrapped it. Cheap Chinese material. Luckily I had enough to make a second, which worked out fine. I also got a Hofner pickguard and some smaller pieces from the same blank, and I am working on a matching headstock logo from the remaining scrap. So I guess I got my money's worth out of it.

So all in all, I'd say it working out pretty well. I'll post some pictures when it is ready for prime time.

And Here It Is ... "Classic Vibe - Modern Player" Tutmarc Audiovox Bass

Specs:

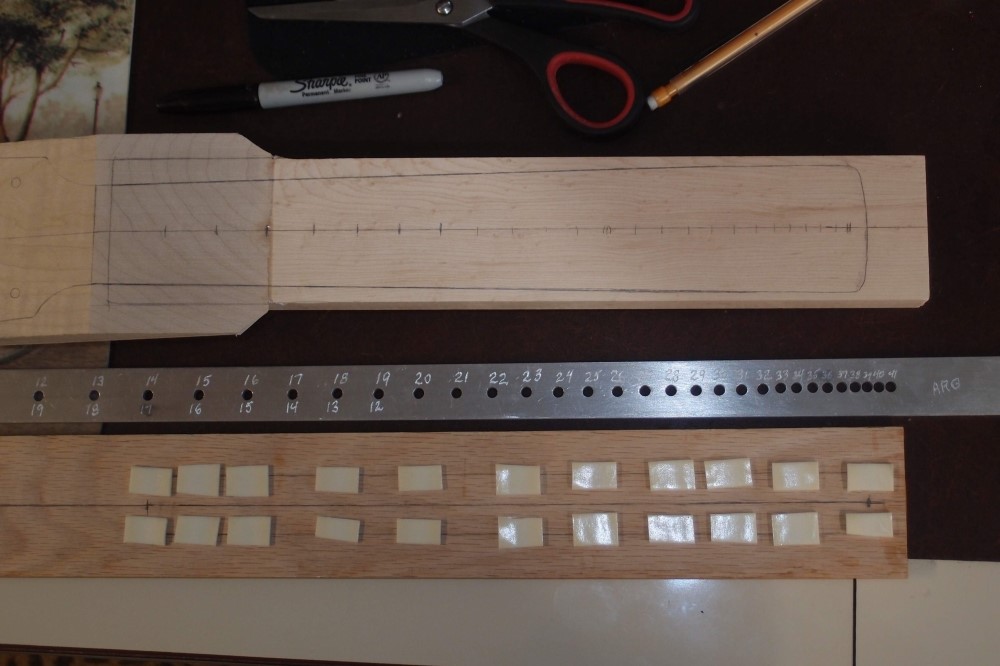

Neck

- wood: 7/8" walnut, Fender-style flat headstock & heel

- fingerboard: rosewood StewMac, cut down to 32" scale, re-radiused to 12"

- frets: 20 Fender Jumbo nickel, 20th fret overhanging

- tuners: Gotoh compact sealed chrome 2+2, inners reversed

- nut: Gibson-style brass, hand-made, Precision-spacing

- truss rod: salvaged Epiphone double-acting, shortened 2"

- attachment: bolt-on, chrome ferrules, SS screws

- logo: inkjet decal on pearl plastic, lacquered

- misc: 1/4" pearl markers, Fender black string guides

Body

- wood: walnut, 1-3/4" thick, laminated from 2x 7/8" pieces, 3/8" edge radius

- bridge: adjustable high-mass chrome, 18mm string spacing

- pickguard: aged pearl plastic, SS #4 screws, walnut thumbrest

- strings: d'Addario roundwound 50-105 medium scale

Electronics

- pickup: cheap Belcat dual-blade humbucker for Strat, 4-wire, 11k in series

- pickup switch: on-on-on mini for series / single coil / parallel modes

- controls: stacked 500k volume & tone, .68uf tone capacitor

- output: oval chrome side jack plate

Misc

- finish: deep polished Danish oil, clear

- overall weight: 7.4 lbs

- overall length: 42"

- cost: $300

Notes:

I never intended to build an accurate reproduction of an original Tutmarc. The 16-fret banjo neck on those looks unplayable, and the electronics are primitive. This is more of an "inspired by" ... I kept to the original aesthetics as much as possible while building a modern instrument on a budget. The rounded contours of the bridge, the blade pickup, big black knob, squared-off neck heel, and compact tuners all suggest the original, without giving up anything in playability, tone, range, or function. You could take this thing out on a gig, and you can play it any style you want, from pick to slap.

The stacked knobs keep the one-big-knob aesthetic while adding a tone control. The extra switch is tiny and easily overlooked, while the strap buttons and string hold-downs are black to blend in, because they really shouldn't be there. There is no way I was going to hard-wire a cord into the upper bout, the side output jack is conventional. The whole thing is scaled up about 5% from what I think the original dimensions are, assuming the original scale is 30.5". No extra holes for the thumb rest, which can be mounted in either of 2 positions or left off.

On the back view, you can see how I solved the string pull problem of the reverse-tapered headstock without having the tuners wind all crazy. This also gives sufficient spacing for the bigger tuners, which would otherwise not fit, since Tutmarc originally used small guitar tuners. Likewise, the strings all just barely clear the fat bass string posts. The brass nut was made from bar stock after the original black plastic one broke. This is the first time I've made a nut from brass, it is very soft and easy to work, and doesn't break like plastic. I also like aluminum for nuts.

The finish is basically varnish, which is what you end up with if you use enough Danish oil. Takes forever, I would not recommend it, and will probably never attempt it again. I must have used a gallon of Danish oil building dog-proof furniture in the past year, but it takes too long to get a guitar-quality finish. The color you see is just the wood, no stain at all. I also tried the Danish oil on the fretboard. I would never do that again, it just didn't come out like you'd want, and it took a while to clean it back up.

Walnut is very nice to work with, pity it is not more available in guitar-sized pieces. Very strong and hard, but not as brittle and chip-prone as maple, with a slightly open grain that I filled by wet-sanding in the oil. Now I have lots of scrap-sized pieces left over that I'm sure will find uses. I've already built a walnut floating bridge and tailpiece for another project. Walnut takes glue much better than rosewood and is as strong as maple but not as hard. My guess is that it is not hard enough to securely hold frets though, that would be an interesting experiment.

It plays really very nice, and will only get better as everything settles in and I continue to tweak it. The neck feels like any modern instrument, which should be no surprise, it is patterned after a standard Fender neck. The small body leads to inevitable ergonomic issues, but no worse than a $10,000 Steinberger. Balance is not as bad as you would think, with the fairly lightweight tuners and heavy bridge for a counterweight. The bridge is a pot metal pain in the ass to set up, I will never use another one like it.

The pickup is a mass-produced Chinese cheapie, they probably have no specific resistance. They are "strat-sized", dual rail, with 4 leads that can be separated for coil switching tricks. Since they are made for guitar string spacing, you either need to use a narrow bridge like a Mustang, or place it close to the neck. It will not cover a standard bass string spread near the bridge. Since you are not using it for its designed purpose, what do the original specs matter? If it works, it works. And it does. I found a good deal on 10 of them, paid no attention to the specs.

Sounds great. I really had no idea what to expect in terms of tone for this setup and had a lipstick pickup waiting as a backup in case it didn't work out. But I must say I am very pleased with the sound. The guitar pickup works perfectly, with strong even output across all strings, and no noise. The pickup switching modes are very useful, you can get anything from a Precision to a Jazz sound. The fact that you can get such a range of great bass tones from one cheap guitar pickup ( that I selected more for its looks and price than anything else ) just goes to show how much BS there is in the guitar industry! The tone control has an extended range thanks to the bigger cap, you can wipe away any trace of highs, and get all Gibson-muddy if you want to. All the electronics are mounted to the pickguard, nice and neat.

These pictures are still not quite the final build. The tuners are a little crooked, the pickup is a little crooked, the nut is not fully cut, the fingerboard is kind of ugly, and the finish is still not 'finished' - you can always buff it out and rub on another coat with oil. But nothing really noticeable is going to change from here. Most of these issues have already been fixed.

May 20, 2014

The Audiovox is hanging by its tuners while the finish hardens off. Going to be a while longer. The neck has taken a nice bow, and the action has gone pretty high. As expected - wood creeps under static load, that's why there is a steel truss rod. A few more weeks and I'll take it down and finish setting up, the nut can be filed some more as well. Till then, it is a wall decoration.