Rickenbacker 4001 Bass 1 (2/5)

Jan 30, 2019

The body frame - dumpster plywood, aged for tone. Making the neck mount separate from the body frame allows nice sharp corners that would be problematic otherwise. I'm leaving this body as solid as possible for better balance.

Feb 6, 2019

All built. The faces are white dry-erase board, sanded on the back to take glue. The pickguard is the same material on the other side. The pickup mount is a plastic wall switch plate.

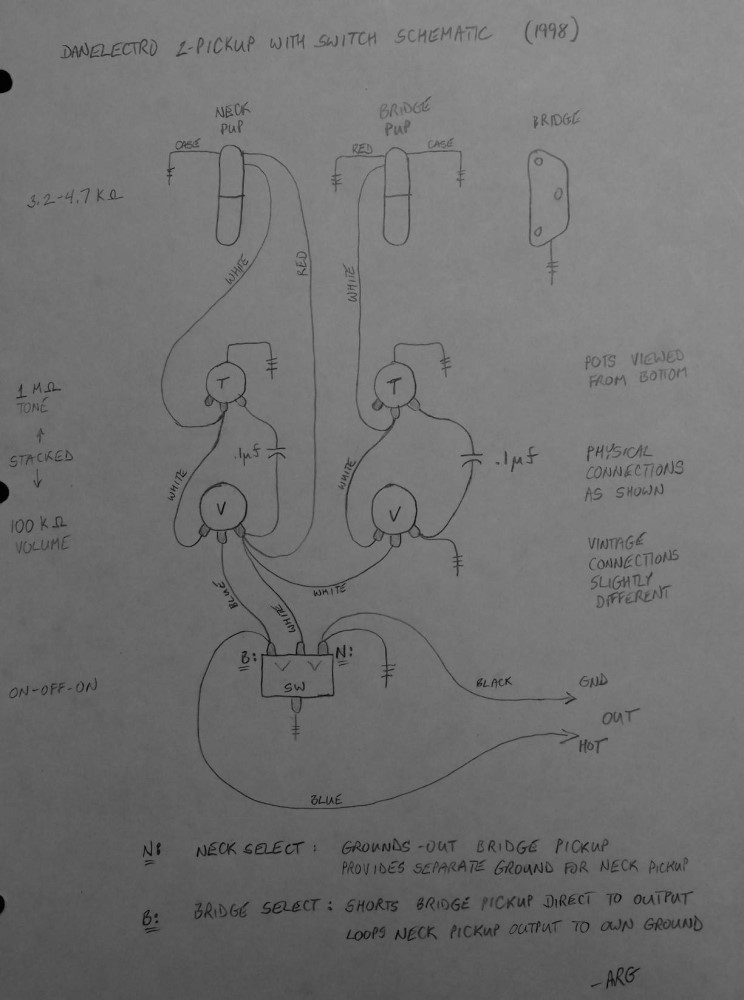

The wiring is classic Danelectro. That white RIC body would look great with sparkly black shark-fin inlays.

Beginning the neck build, This neck will use a Radiata fretboard over a Radiata base - 100% pine construction!

Unfortunately, this neck is about to be ruined in the binding slot cutting process, thanks to 3M double-sided tape, which ages to useless in less than a year. I have switched to Dollar Store tape, which is 1/10 the price and works better.

Mar 1, 2019

Here we go again ...

The outline is not centered on the board. That way I only have to glue one piece on. What makes you think the board was centered on the tree?

Finished-off the headstock, then rough-shaped the whole thing on the Ridgid oscillating belt sander. Note all the sander chip-out ... there isn't any !!! All you router-heads should learn something here !!!

Now to cut the truss rod slot. No avoiding the router for this.

This is actually a much neater job than the ruined one. Note how the rod for a 34" neck barely fits into a 21-fret 32" neck. Barely is good enough.

Cut and sanded the headstock to thickness. Regulation is 9/16", I left this a little thicker, because this is not maple. Almost back to where I was before, and feeling better about things. That's enough for now.

Dollar Store double-sided tape works great and is even pre-cut into convenient pieces. So 3M can go to hell.