Silvertone 1472 Amplifier (1/3)

After successful and interesting experiments rebuilding 1448 and 1457 "Amp-in-Case" amplifiers, I thought I'd try something bigger. So I kept an eye on the eBays, and eventually came up with this - an early production Silvertone 1472, made by Danelectro and sold through the Sears catalog. It was fairly cheap because it wasn't working. However, the cabinet is solid, the aluminum faceplate and labeling are in good shape, all the knobs are there, and everything else can be replaced or rebuilt. The Tolex is in very good shape, and the corners of the cabinet are all pretty much intact. Much like buying an old car - a blown engine is easier to fix than a rusted-out body.

That's $659.77 in worthless 2022 dollars!

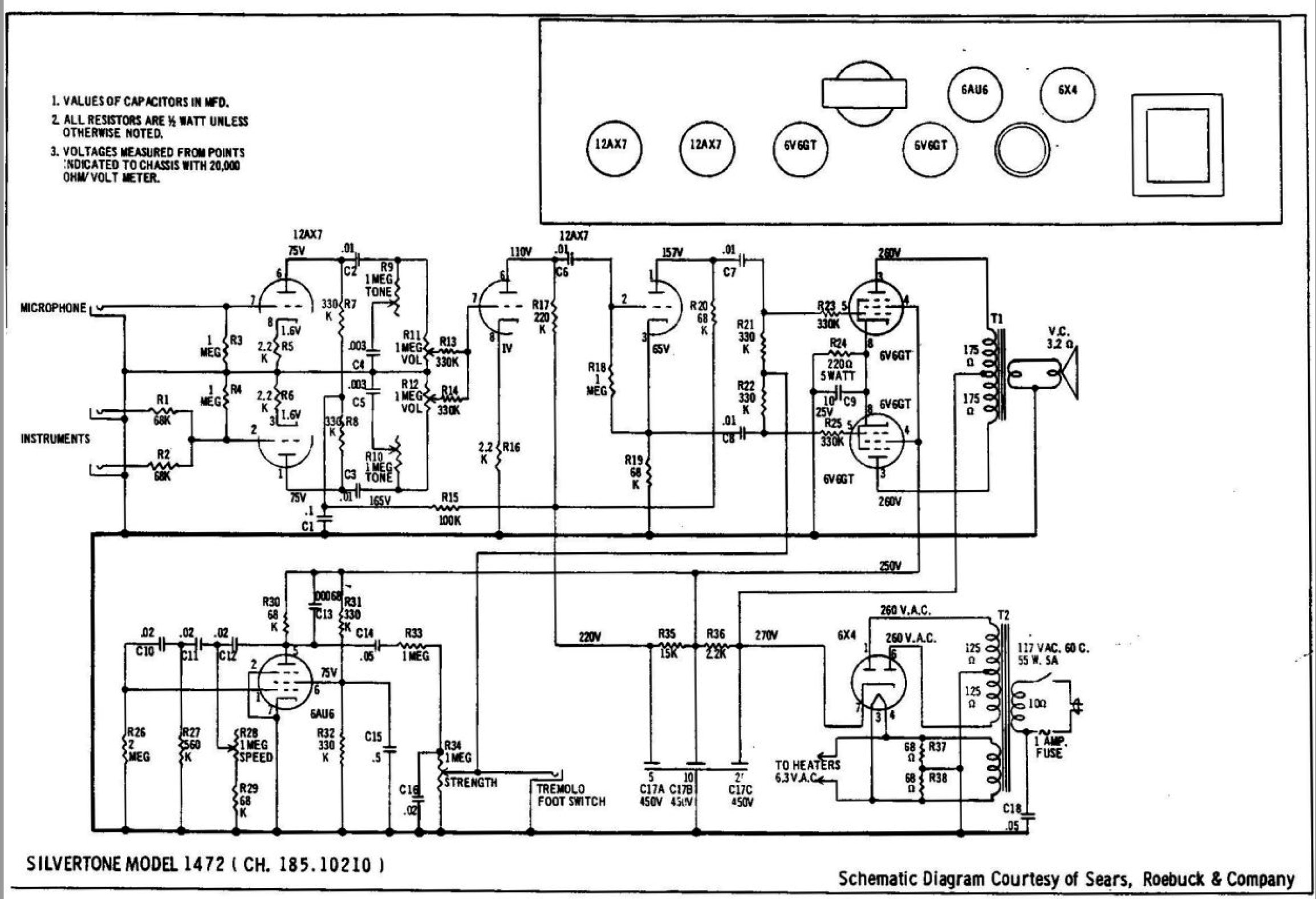

The 1472 was introduced in Fall/Winter 1961, which matches the date code on the speaker. A couple of other things point to this one being an early production example. Later production used a diamond cutout for the speaker, and replaced the 'refrigerator' handle with a normal strap handle. Finally, the amp circuit was actually missing a couple of resistors, R23 and R25, that are on the schematic. I suspect those were added after this amp was built. However, the biggest giveaway that this was one of the first ones off the production line is the missplling of "Tremlo" on the control panel. The Danelectro number on the chassis is 185.10210. The Jensen date code on the speaker frame, 220141, decodes as the 41st week of 1961 - October 9-16. Sears probably sold this amp over Christmas 1961. The 1482 replaced the 1472 in Fall/Winter 1963.

The speaker baffle on this amp is the same 1/4" masonite that many Danelectro guitars are made of, and most of the screws had torn out. So I glued a piece of 1/4" plywood to it, and in so doing, covered up the date code, which is now forever lost. I could kick myself. But the repair is solid, and leaves the grille cloth undisturbed. The grille cloth was in nice shape and only needed some cleaning, and the Tolex got some Armor-all. The mounting screws were precarious, so I solidified the screw holes with Crazy Glue. I did the same all over the cabinet - just drip the glue into the hole and let it soak into the old 'wood' and set up, forming a space-age composite. I also re-glued any loose joints with wood glue.

Here is what was left of the original Jensen speaker. The magnet was barely attached, and fell off just from handling. Jensen still produces this model, C12R, so I ordered a new one online. This amp uses an 8 ohm speaker, some use 4 ohms, depending on the output transformer; some can use either. Does the new one have 'vintage' 'tone'? Well, if by that you mean 'does it sound like the voice coil is shorted, the magnet is mostly dead, and the cone is dry-rotted', then probably not. If you mean 'does it sound like it did when it left the factory?', then I'd say, probably yes. Jensen does not seem to have changed the design at all.

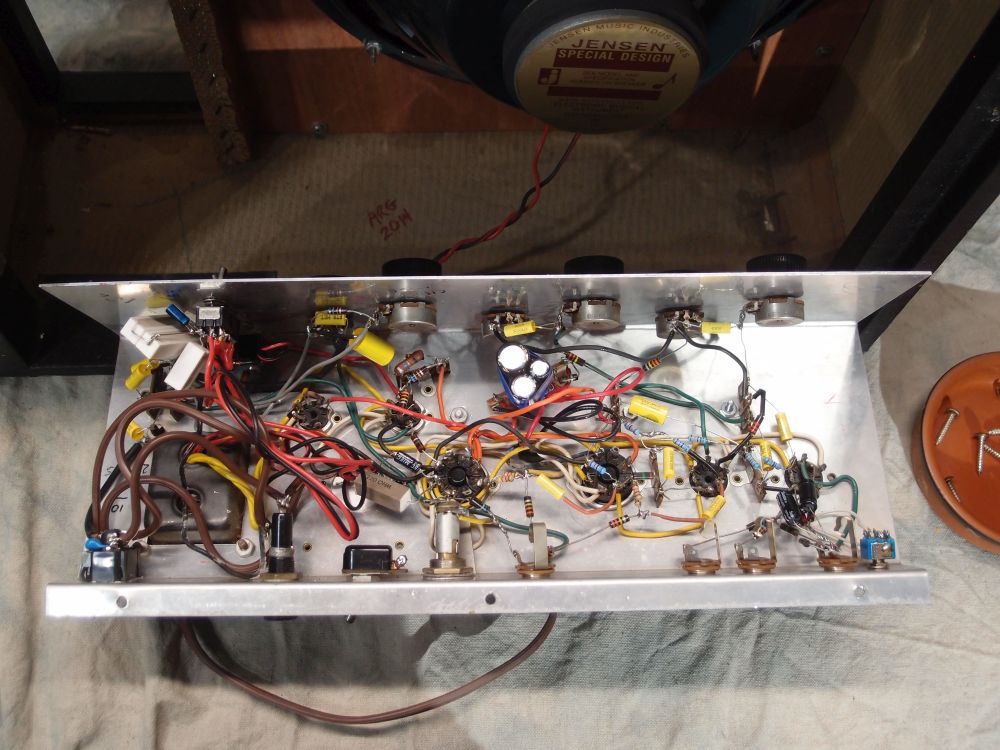

From left to right, the components are:

- pre-amp tube - 12AX7

- phase splitter tube - 12AX7

- power tubes (2) - 6V6GT

- output transformer [behind power tubes]

- tremolo tube - 6AU6 [behind]

- power supply capacitor can (replaced with attenuator)

- power supply rectifier tube - 6X4 [behind]

- power supply transformer & cord

These are all common tubes, still readily sourced to this day.

So on to the electronics. Above are some pictures of a stock 1472 from the internets, since I didn't think to take any before I started. All the green barrels are infamous Sangamo capacitors. I'm no expert on antique electronics repair, but I can save you a lot of trouble: if you see green, replace it. I tested all of them after I cut them out, and every one was way out of spec. The amp above has already had a few capacitors replaced, those are the yellow barrels. There are also three electrolytic capacitors in the power supply. You can just assume they are bad and replace them. You don't need an oscilloscope for this. In fact, for an amp of this age, just assume all the capacitors are bad and replace them - they are not that expensive.

Then I moved on to the resistors. With the tubes pulled, you can test most of the resistors in-place. I replaced anything that was more than 10% out of spec. Again, you don't need an oscilloscope, all you need is a multimeter. So far, so good, I powered it up and tested it, and it worked, except for the tremolo. Some circuit tracing revealed that R32 was wired wrong at the factory. The tremolo came up strong once I fixed that. All together, I replaced 19 capacitors and kept one ( ceramic - they generally last forever. ) I replaced 12 resistors, kept 14, and added 2, not including the pots, which were all fine after some cleaning. One advantage of these Silvertone amps is that tube biasing is automatic, so you don't have to mess with that like on most other amps. So you can rebuild one of these Silvertone amps with nothing more than a multimeter and a soldering iron.

I see videos on the Youtubes of 'professionals' doing this sort of work, and they spend a lot of time trying to determine which parts to replace and which are still barely clinging to life. I don't get it, parts are cheap, skilled technician time is expensive. * This amp is over 60 years old! You can just assume everything is bad, no need to waste time testing. It can take longer to test something than to just replace it, and a lot of things have to be removed to be tested, why put them back? I only tested the capacitors after the fact, out of curiosity, and every one of them was bad, and some of them were very bad. Keeping old components to maintain 'vintage tone' is actually doing just the opposite. Restoring circuits to factory spec is going to give you 'vintage tone', not preserving the old worn-out components. It's like the idiocy that dominates luthiery has seeped into electronics. What would a luthier have done about the missing resistors and mis-wired tremolo? Is that 'vintage' too?

* Oh wait, now I get it.

Questions or Inquiries?

Just want to say Hello? Sign the .