Fretboards

Here is an assortment of woods that would be hard to put together. All of these are radiused to 12", sanded to 100, and liberally coated in Minwax Natural stain to make the grain and colors pop. They are all 2-1/2" wide, and started out 1/4" thick. These are:

1-3:

Flamed hard maple from Lowes. I love this stuff and always look through the pile to see if there are any pieces that are special. You might also find birdseye.

4:

Plain hard maple from Lowes. This one is as plain as you can get - the grain looks like it was drawn with a ruler. You can always find a usable piece. Maple has a fine closed-grain but needs finishing to stay clean.

5:

Would you believe this beautiful piece is cheap Red Oak from Home Depot? I had to rip it to width. Didn't look like much until I hit it with the stain, then wow! Like yellow rosewood - I can't wait to try this for something. I have another piece I'm going to try blackening. The open grain will need filling and finishing. Oak is slightly softer than maple, but very hard compared to most woods.

6-9:

Jatoba, or "Brazilian Cherry", from WoodCraft.com. This is a very inexpensive wood that is often used for flooring. Very hard, open-grained, like rosewood, but not oily, so will need a finish.

10-11:

Bubinga(?) from WoodCraft.com. I've had bad luck with Bubinga, it seems to warp in storage, and some of the pieces I received were so ugly that I complained and they refunded me. The short piece is one of those that I cut the worst off of. I have trouble believing this stuff is Bubinga.

12:

Purpleheart from WoodCraft.com. Wow! Very hard and abrasive wood, you can feel that as you sand it. Close grained, even and straight, and not all that expensive. All of WoodCraft's pieces are 3" wide, I ripped them down, and I took the Purpleheart scrap and make a bunch of really neat dot markers.

13:

Black Walnut from the hobby shop around the corner. Walnut is a hard wood, not as hard as Oak or Maple, but a lot harder than Cherry or Mahogany. This is another experiment, I think it will work fine. The other commonly available hardwood is Poplar, which is in reality not hard at all. Other woods like Cherry are likewise probably too soft.

14-16:

"Rosewood" from StewMac and eBay. The piece on the left turned almost ebony with the stain. Nowadays "Rosewood" can be almost anything.

The tropical woods are about twice the hardness of the domestic woods. My feeling is that degree of hardness is complete overkill. When spec'ing out the Les Paul for production with Gibson, Les Paul felt that a guitar should be made with 'fine woods', which is probably how rosewood got started. Funny how he also considered Mahogany to be a fine wood, when it is actually cheap bulk crap. That's why Gibson used it, although they certainly charge a premium price for it. The same goes for Korina. On the Fender side, Alder is basically just firewood - a trash tree that grows all over California. My point is, these woods are used in luthiery for all the wrong reasons, or no good reason at all, and I doubt you really need a Janka hardness over 3000 to hold a fret in place.

The maple, walnut, and oak are all available locally in 1/4" thickness. They are very inexpensive, and I can hand-select my piece. You might be able to source Jatoba from a flooring supplier, but you'll have to plane it down. You can get almost anything from Woodcraft, StewMac, or eBay, but you have to buy it sight-unseen, which can be hit or miss. I like being able to pick my pieces.

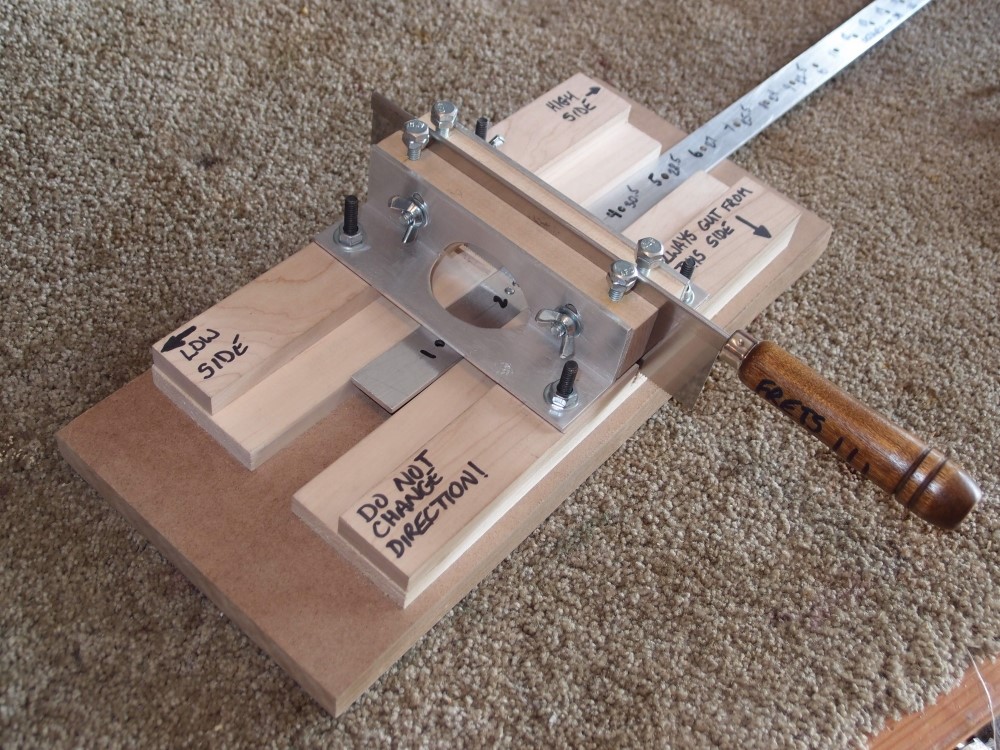

I also found another way to radius these pieces. The rough-in can be done on a bench belt sander. Since the workpiece is longer than the sander, you must keep it moving constantly, if you stop, the rollers will dig a gouge in that spot. You want to hold the board nearly flat and grind off most of the material to make the curve you want, then finish with a sanding block. This requires just the right touch, it is really an art, and I was surprised that I was able to pull it off. Most of the boards were roughed-in with my radius jig and a router, then finished with one of my sanding blocks.

My sanding blocks are completely better than StewMac's because they are a full 3-1/2" wide. StewMac's blocks are exactly the width of a 2-1/2" blank, which means you have to guide them more accurately than is humanly possible, and I've never had a piece turn out good. With my block, I put the workpiece atop a scrap of 2x4, which matches the width of the block, making a natural guide, and I've never had a piece turn out bad.

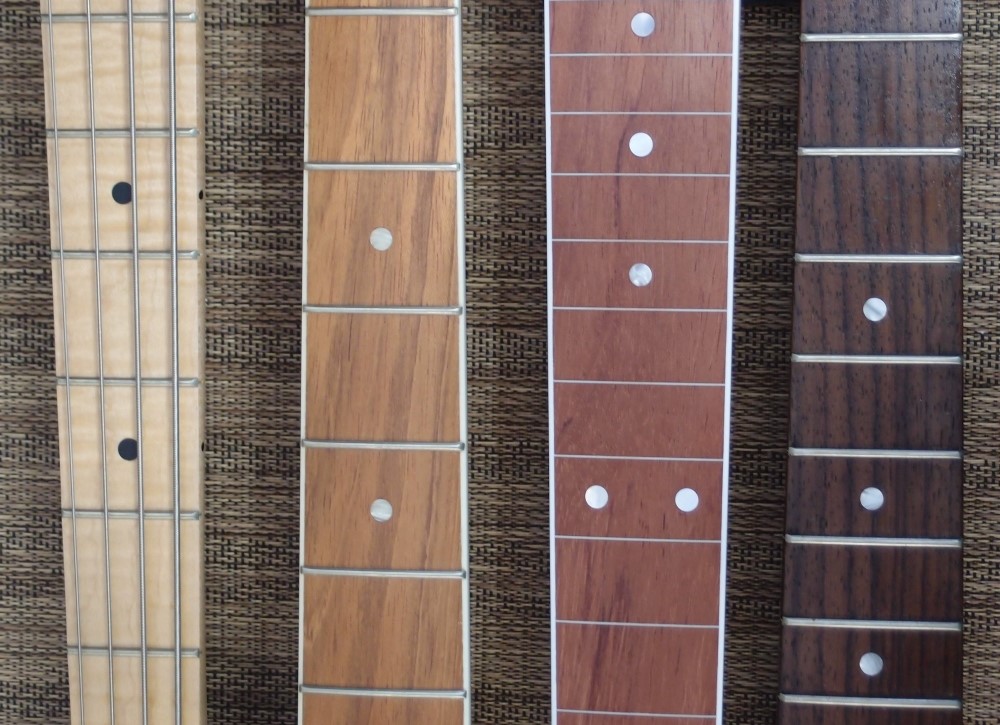

Since I happen to have three different necks lying around at the moment, here is an interesting comparison of fretboard woods.

From light to dark, these are:

- flamed maple

- bubinga

- granadillo

- rosewood

The flamed maple is from Lowes, a lucky find. I look in from time to time to see if they got any new stock, most of it is plain, in lengths of 24" and 48", 1/4" x 3", and quite inexpensive. Plain maple is nice too, but stay away from anything spalted - that would be softer and probably not suitable. The Bubinga and granadillo are from Rockler, reasonably priced 1/4" x 3" x 24". The 'rosewood' ( many things are sold as rosewood nowadays ) is a pre-slotted piece from StewMac I think. Bubinga is Rickenbacker's standard fretboard wood.

The maple and Bubinga are finished in satin polyurethane; the granadillo is awaiting the same finish. The rosewood is freshly oiled with linseed, which has much better staying power than 'lemon oil'. The purpose of sealing the lighter-colored woods in plastic is to prevent them from blackening with dirt and finger oil over time. Conversely, rosewood is already dark and oily, adding some extra makes it shine.

The black dot markers are cut from a piece of pickguard scrap with a 1/4" plug cutter on the drill press, the rest are bought pearl. I also like to use maple dots on a rosewood board, and rosewood dots on a maple board - it is the contrast that you are after, and the result is attractively 'woody'. All made for free from scrap. There are many things you can make dot markers from once you have an inexpensive plug cutter; it is rumored that Fender's famous 'clay' dots were cut from old gray floor tiles, which I could very well believe. This only works for solid materials though, pearl pickguard material is likely only pearly on the surface, which would get sanded off when you level the dot. The pearl dots are solid pearl. All the side markers are plastic rods from StewMac - super easy to use. The binding is from a big batch I bought from China.

For future experiments, I have pieces of purpleheart, walnut, and oak to try out. Rockler has tons of interesting exotic woods that would be suitable for a fretboard. What is needed is a very high Janka hardness - maple is the softest here at 1450, while granadillo is the hardest at 3590. The hardness is to hold the frets, and also to resist surface wear from the strings, although the frets take most of that. Oak is as hard as maple, but the hardness is uneven across the grain. Walnut is softer, but I think it will work if the frets are glued. Strength is also important, as the fretboard is an important structural part of the neck, but all of these woods are quite strong as well.

Finally, what about the effect of the fretboard on the tone? Well, obviously, rosewood sounds darker, while maple sounds lighter. Seriously, does anyone actually believe this cr@p? There is absolutely no difference in the tone. NONE. Nothing that could possibly be scientifically measured. The same goes for the entire guitar unless it is a hollow-body, and even then the effect is minor. If you want to convince yourself different, go ahead and fall into the marketer's trap. There is no difference. I'm not talking about acoustic guitars, or Stradivarii, but amplified electric guitars. The concept of tonewood does not apply, except as an excuse to charge 10 times what a Les Paul is really worth. And the finish has no effect either.

Duncan:

January 4, 2022 at 3:45 PM

Great, finally a guitar builder who speaks my language. Its good to hear someone approach the 'mystical' art of Luthiery using plain common sense. No, they are not Stradovari (Stratovari?), they are functional pieces of engineering hardware. Did Fender really decide to use Alder bodies for their tonal properties? No, he chose it because it was easily obtainable and cheap, offering a higher profit potential.

So, in order to capture the magical tone of a Hendrix or Clapton you must play an overpriced piece of 1960's firewood? No, all the magic was in their fingers not in the 'wood'.

I am however, somewhat envious that you are able to find wood species such as Maple in your local hardware store. Here in the damp and dingy UK its pine, plywood or the Brian May route; buy an old piece of furniture (preferably from the 50s or 60s because of its superior tonal properties) and build from there.

Thank You