Stratocaster Micro Bass 1 (1/3)

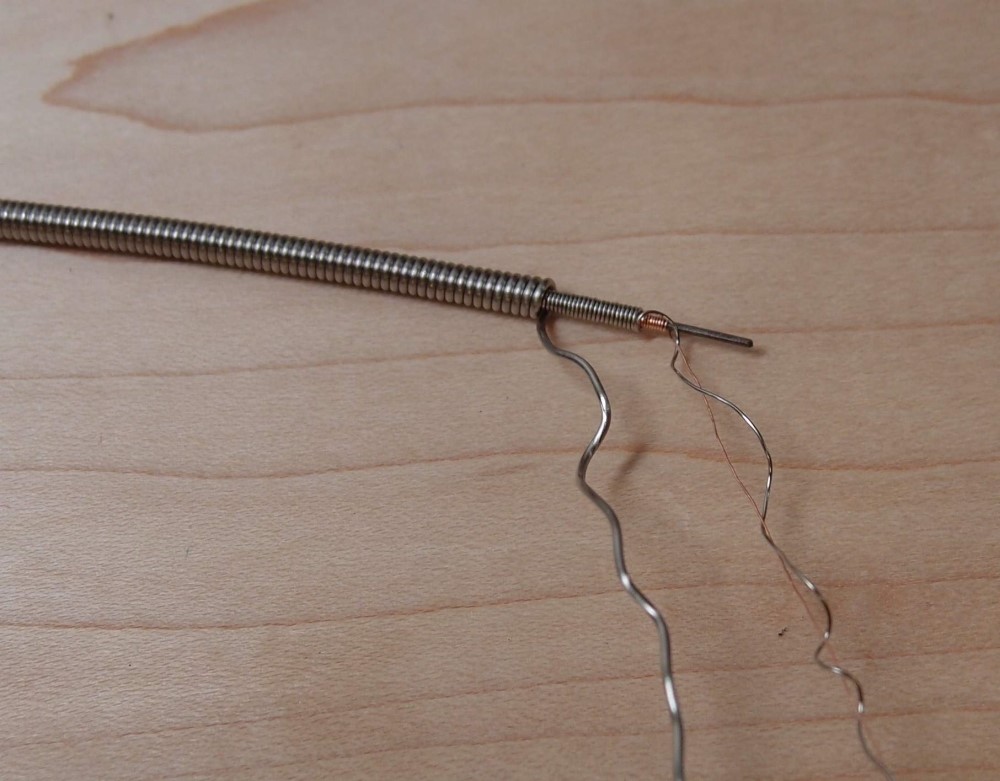

Eden paddle-head guitar neck converted to bass. Strings are lower four of 5-string set, unwound to fit 25" scale.

A few build details:

On the left:

- Probably a Squier body, buffed and polished

- Eden paddlehead Strat neck, cut to a slightly enlarged guitar headstock profile

- laser-printed decals, poly finish

- Chinese zinc-cast bridge, 18mm string spacing to match the neck - eBay

- GFS Jazz neck pickup

- Fender Japan P pickup, mounted narrow to match the neck

- 4-way blade switch - series/parallel

- passive electronics - bass & treble cut

- Chinese fake Fender 125-50 roundwound strings ( pretty bad )

I haven't decided what I want to do about the strings yet, but other than that I am quite happy with it. Really fun to play, nice tone - anywhere from P to J, and crazy roar in series mode. Weighs around seven pounds. To mount the bridge and pickups, I filled the tremolo hole and spring cavity with plywood. The bass pickups required some routing. The pickguard is obviously totally custom, and pretty crowded.

To make these strings, start with a 5-string set, and unwind the B down to the necessary length to fit the tuner. That becomes your E. You may also have to do the same for the E/A, the rest should fit.

Questions or Inquiries?

Just want to say Hello? Sign the .