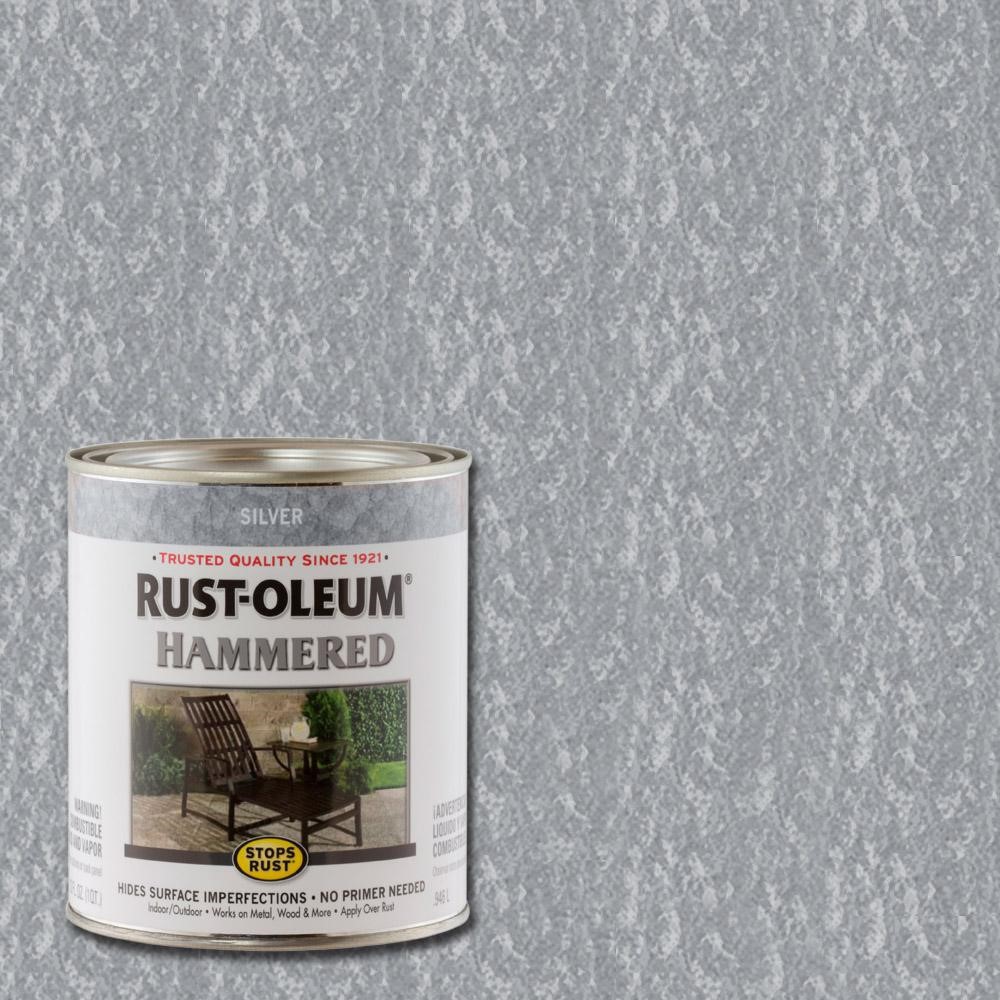

Hammered Paint

Hammered spray paint is formulated to produce a mottled two-tone finish. The surface is smooth but not perfectly even and can be anything from matte to high gloss metallic. Hammered paints are available in a range of colors at any hardware or hobby store.

Hammered paints have a number of advantages. They cover small imperfections, require no polishing, and are hard and tough. I can think of nothing else that would stand up to buckle rash better. Application couldn't be easier. Just spray it. When you think it is thick enough, stop.

A hammered paint finish works especially well with Danelectro-style side binding. You actually don't want to paint the sides, just lay the part flat and shoot. You could also just do the back of the guitar hammered, and do something fancy on the front, like a veneer or a sunburst. You could even shoot a hammered burst.

I wouldn't use a hammered finish on the back of a neck, though. That is one place you want to be as smooth as silk. The front of the headstock would be fine.

Hammered paint is also available as an oil-based brush-on. This might work even better than the spray can. It might also be spray-able with a compressor. All things to try someday.

Krylon hammered pain is less blotchy than Rustoleum, which gives two useful options.

Questions or Inquiries?

Just want to say Hello? Sign the .