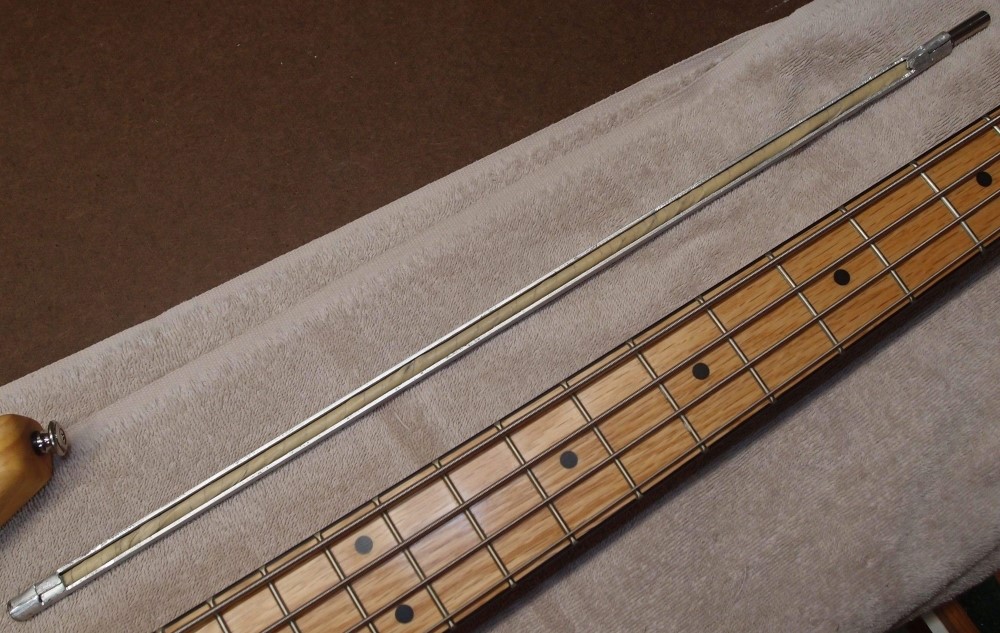

Martin-Style Truss Rod

This is a Martin-style single-acting truss rod. I built it years ago and never used it, and at this point, I never will. I am breaking it up for parts, so I thought I'd post a picture first. It consists of a 10-32 threaded rod in an aluminum channel. At the fixed end, at the lower left, the rod is set in a T-nut and the end is peened (hammered) over to keep it from rotating. The adjusting end is nothing more than a washer between the nut and the channel. Both ends are secured by bending the channel over them, then the center of the channel is cut down and everything is ground to minimal dimensions. You can find detailed directions online.

The neat thing about it is, you can build this on your kitchen table with not much more than a hammer and a hacksaw, and the parts are all available at Home Depot, in fact, you could use a coupling nut instead of a fancy guitar nut. How does it work? Just fine. The rod is in tension against the channel, in compression, which causes the channel to bend toward its open side. It might look crude, but it's still better than a skunk. An advantage of this rod is that it requires a less-deep channel than my newer model, although wider, about square.

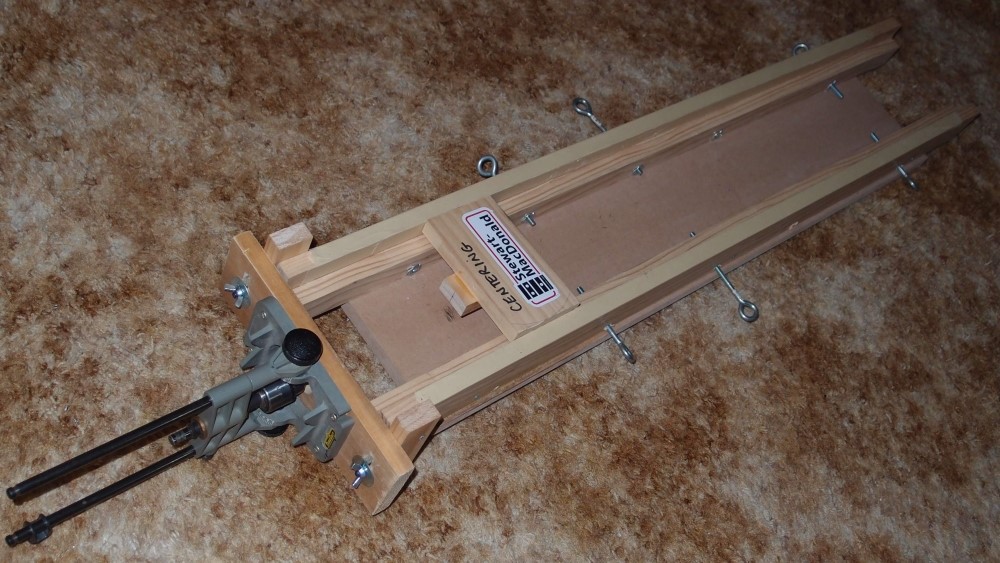

I did an informal test the other day. I took both this and my latest truss rod and cranked a nice bow into them. Then I put one end on a scale and twisted the other end until it was straight. The resulting force on the scale was about three pounds. I did it several times with both rods, and always around three pounds. This is not scientific in any way, but it does give some idea of the amount of transverse force generated by the truss rod - it is very small. However, the amount of tension required to generate that small transverse force is orders of magnitude greater, and in the case of a skunk rod, all of that force is directly on the wood of the neck. No wonder old necks twist up.

Post Mortem:

When I build 'em, I build 'em. That thing did not want to come apart. Out of curiosity, I peeled all the tape off, and that is a store-bought threaded rod. A threaded rod makes a fine tension member but is not good for compression. It appears I brazed the T-nut on. That is easily done with a propane torch and solder from Home Depot, any kind of solder should do just to bind up the threads. Do this before assembly, don't put the torch on the aluminum, you'll ruin it. Or you could degrease it really good and Crazy Glue it. I haven't got that much faith in Crazy Glue.

Questions or Inquiries?

Just want to say Hello? Sign the .