Fret Saw

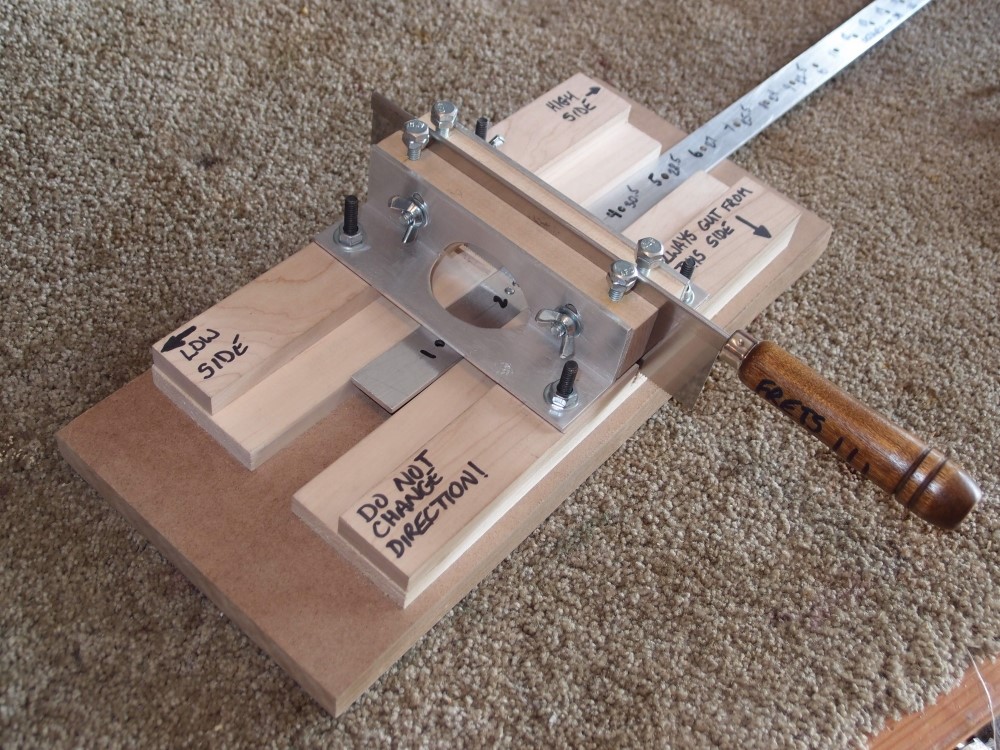

This is the saw I use for cutting fret slots - a Zona 35-380 dovetail saw. It has the correct kerf of 0.022" for a fret slot, and has an 8" long blade, is long enough to work with my slotting jig. ( StewMac's saw is 0.023". ) The spine on the back engages the jig to set the cutting depth. Well, actually, I got the saw first and built the jig around it.

These are available from many hobby supplies sites for about $10 + S&H. Get several, as they do wear out. While a slot might take 30 strokes to finish in maple, it can take twice that in ultra-hard tropical hardwoods. It is less a matter of the teeth going dull than wearing down sideways - the outer corners wear off. I can even feel it with my fingers. The result is that the cut gets narrower, and eventually, the saw binds in hard woods, at which point it may still be useful for a lot of things, but not for fretting anymore.

I am down to my last good saw. The one I've been using a lot now measures as little as 0.19" in the center, 0.020" at the end, and still 0.022" by the handle, which is hardly used. I noticed when trying to insert 0.020" plastic strips for marker lines on a fretless, and they wouldn't go. That's only 3 thousandths of an inch, but the saw is already one-thousandth narrower than a 'real' one, and 0.004 / 0.022 = 18% error. The heel of the blade won't slide through the slot you just cut, although I've been using it to widen them out to spec.

A too-narrow fret slot in a very hard wood could introduce excessive compression in the fretboard, which could cause the neck to back-bow. Depending on the truss rod, this can be an irrecoverable disaster. On the other hand, I left the narrow slots in an experimental walnut board I'm making, as walnut is softer and can probably use the extra grip. I'll keep the current worn-down saw for experimenting with oak, walnut, and maple, and use a new one on the Jatoba I've been using, which is noticeably harder than rosewood. A third one of these saws that is completely ruined for fretting is still handy for all sorts of small cutting jobs in soft woods.

You can get 3 of these little saws for the price of one 'luthier's' saw, and they work great. The $30 saw is not likely to last any longer than the $10 one, and certainly not as long as 3 of them! Time to order a couple more. The Zona 50-350 saw will also work in a pinch, but with a shorter blade with fewer coarser teeth, it will wear out faster. It is also a different height than the 50-380, so you can't go back and forth between them without adjusting the jig for depth.

Continued ... I just measured a bunch of different frets, and got readings from 0.017-0.018 for Fender frets to 0.022-0.023 for the bulk wire I've been using lately. Two conclusions from that: measure your frets and pick the right saw for them - that 'worn out' saw doesn't seem so worn out now. And obviously, it is the little teeth on the tang that are doing most of the work, because those Fender frets are much narrower than the slots I've cut for them over the years, but they are in nice and tight.

The little teeth on the fret tang measure 0.037" on the Fender wire, and 0.044" on the bulk wire. Both of these are enough to bite into the wood around a 0.022" slot. That is what holds the frets in place. Glue will fill any gap between the tang and the slot, and solidify the assembly. What you don't want to do is shove a 0.023" tang into a 0.010" slot, which you would get from most razor saws. That would be a sure recipe for fretboard compression and back-bow. A couple of thousandths of interference is probably a good thing, but not too much. I need to get some feeler gauges and measure some actual slots. I vaguely remember calculations for interference fits ( 'press fits' ) between metal parts from college. Of course, wood is going to be more forgiving than metal - it is softer.

And another conclusion: glue your frets in. White glue is good enough most of the time and cleans up easily with water. CA works on hard cases but gets all over your fingers and everything else. I used CA to set the lines on a fretless board, but then I sanded away all the mess - not an option on a fretted board.

I've done quite a few fret jobs and some re-frets, and never considered any of this before. I always used a 0.022" saw, and it just worked. There's a lot to be said for 'it just works,' and that saw has worked with every kind of fret in every kind of wood, installed with both a hammer and a press. I guess the old engineer in me awoke my curiosity.

Here's another bit of advice that should be obvious by now: if you really want to know what is going on down to a thousandth of an inch, get yourself a digital measuring caliper. They're so cheap and readily available nowadays, and a little six-incher is all you need for guitar work. I also used a caliper to lay out the holes in the fret spacing guide.

It turns out that Fender really has just one scale - 34" 32" 30.3" 28.5" 27" 25.5" 24" 22.5" 21.5" are all just different spots on the same guide. Extending Gibson's 24.75" scale into bass territory, we get useful 35" 33" 31.2". Doing the same for 25" yields 33.4" 31.5" 29.8". A guide like that would include both the Danelectro/Martin 25" guitar, and the Rickenbacker 33.25" bass. In other words, a guide that has a base scale of 35" would include a Gibson guitar, while a guide that has a base scale of approximately 33.4" would include Rickenbacker, Danelectro, and Martin. A base scale of 34" covers everything Fender ever made, and that's no accident.

How accurate does a fret guide need to be? A guitar is an equally tempered instrument, meaning that except for a few oddballs, all the notes are approximate. In addition, all the frets are a compromise across multiple strings. Most notes are close enough to true ( a few cents ) that it is not noticeable. If you have really fine pitch, the worst note ( furthest-out in relation to the root ) is the third and can be audible. So basically all the notes are wrong to begin with. Then there is the effect of the mass and stiffness of the strings, which is compensated by adjusting intonation, yet another kludge.

So if your frets are just a smidge off, it is not going to matter much. Gibson's Les Paul frets are a lot more than smidge off, and the error is so entrenched that they won't even fix it. But you still want to be as accurate as you possibly can be, and since there is a well-known mathematical formula for equally-tempered fret positions, I can calculate them to the thousandth of an inch. I can try to measure those thousandths with the caliper, and mark, punch and drill them as accurately as possible.

The fret guide I made produces neck scales from 36" down to 21.5" with no tuning issues that I can detect, either by ear or with a digital tuner, so I suppose my best effort was good enough. I would guess my locations are no worse than +/- 0.010", a hundredth or 10 thousandths, and that is a lot more accurate than you could possibly get away with. You could probably do a good enough job with a finely divided ruler, but I wouldn't.

This subject is now officially beaten to death.

Questions or Inquiries?

Just want to say Hello? Sign the .