Stratocaster Bass IV (2/3)

Bass IV Tremolo Bridge

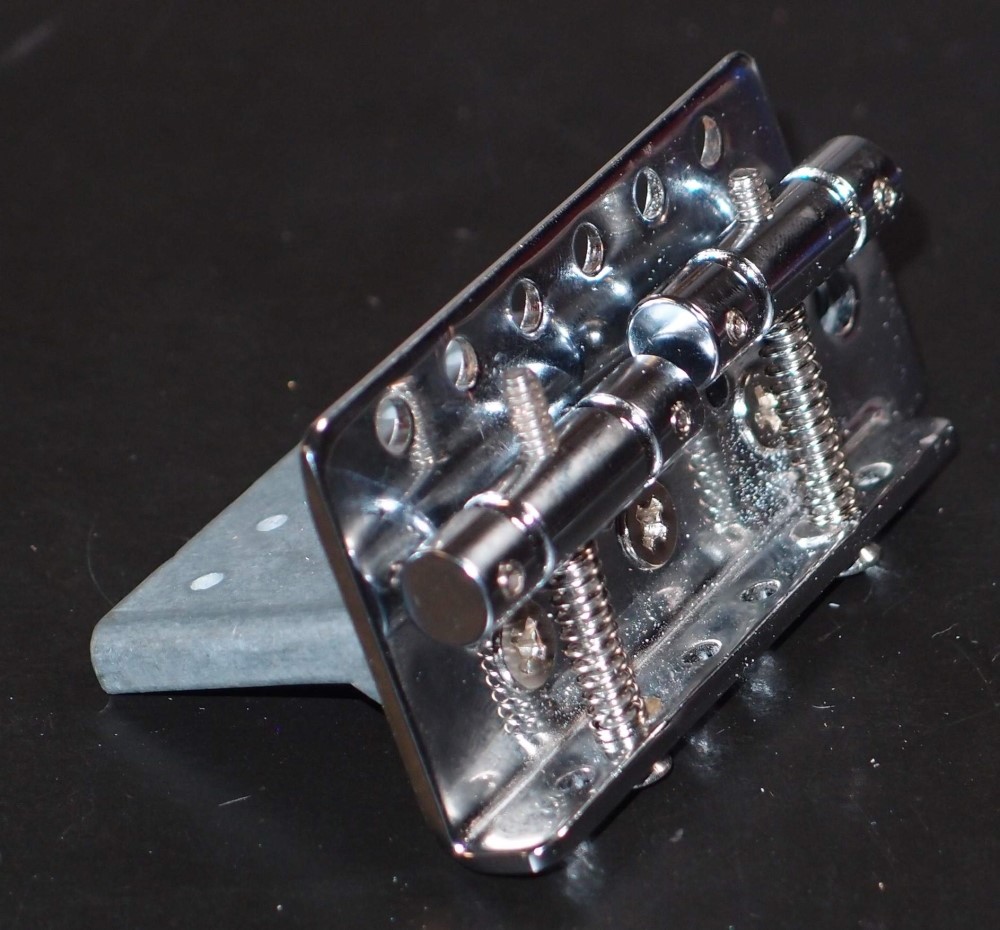

This is a stock Strat tremolo bridge converted to four strings with two saddles taken from an inexpensive Bronco bridge. The new holes for the Bronco saddle bolts need to overlap two of the existing holes. Kind of a problem.

First, I threaded holes 2 & 5 and plugged each one with a steel bolt. I sawed off the bolt so that it just protruded on both sides of the plate, then peened it over to lock it in place.

That gives a solid place to drill the new hole, but that is no easy matter. The chrome plating is extremely hard and slippery, and drill bits tend to flex and skate on it. So I started the hole with a 1/8" bit stuffed as far into the chuck as it would go. Also, the plugs and the chrome surface are different hardnesses, and you are trying to span both with one hole. Punching a starting dimple was no help either. Needless to say, you need a drill press and a vise for it.

I ruined the first bridge plate just working out how to drill the holes. I am not an experienced machinist, but I do have a box full of Strat tremolos to experiment on. A better approach might be to drill out the existing holes large enough so that your new holes are drilled entirely in the plugs. In that case, brass plugs might be better than steel. At any rate, I didn't try it. My very first idea was to fill the holes with silver solder. That was kind of funny, as the solder slid off the chrome like it was glass, and filing the chrome out of the holes made them too big to fill. One good thing is that there is very little stress on the saddle screws, all they really need to do is stay in place, so however you block the old holes is probably going to be strong enough.

I got the holes reasonably well drilled in a second plate. Then I enlarged them with a file in the direction they needed to be, necessitating larger bolts. You can see the now moon-shaped plugs in the photo above, as well as the oval-head bolts that I used, because that's what I had, and the countersunk heads have a nice way of centering themselves. Finally, I re-tapped the saddles for the new bolts. The springs still fit, and it was done, and doesn't even look too bad. The remaining four saddle bolt holes will take the strings, rather than putting them down the block. The outer holes line up perfectly, and the inner ones are close enough, I think. If not, those holes will be easier to drill than the saddle bolt holes. Using the 'top' holes for the strings rather than the bottom holes leaves more room to draw the saddles back for intonation.

An alternative to all of this would be to make a custom set of saddles that fit the existing Strat bridge holes. Starting with a 3/8" brass rod stock, cut off two Bronco-sized pieces. Drill & tap them them off-center to line up with the stock saddle holes, then drill and tap for the height adjustment screws. Finally, add the string notches. Brass is soft and easy to work with, but that's still a lot of work, and I don't have any stock handy, nor the tiny set screws and the taps needed for them. I'd rather just sacrifice a cheap Bronco bridge. I looked at some other alternatives as well, but trading six holes for four is not simple no matter how you do it.

The four lower Bass VI strings left over from the previous post total up a tension of about 100 pounds, about the same as a six-string guitar. So, unlike the Bass VI above, in this case the tremolo is not overstressed and should work as intended. So all these parts and my last three rail humbuckers went into a bin labeled 'Bass IV'. A project for a snowy winter.

Here's something else interesting: if you sand away some chrome, say on the bottom of the plate, you find a layer of copper over the steel. You could have some hope of soldering to that, but I had no such luck in this case. After all the experimenting, that first bridge plate got pretty ugly, but I kept it in case I want to do more horrible things to it.

Second from the right ... I call it a Bass IV. It is inspired by the Bass VI next to it. The Strat tremolo mechanism is overloaded on the Bass VI, it is not useable, I just left the arm on for show. I figured with just four of the six Bass VI strings, the tremolo would work better, and I happened to have an extra set lying around, as well as a body, so ...

Details for the "Bass IV":

24 fret 30" maple neck ( from Home Depot, ) flamed maple fretboard ( from Lowes, ) pretty much the same as the Bass VI. Guitar-sized headstock with compact tuners, to keep the weight down and have some semblance of balance with that long neck. My own custom double-acting truss rod with spoke nut.

Lipstick pickups, wired in series, so positions 2 & 4 quack, like a T Rex. Active bass & treble controls, with passive bypass. I cannibalized a Strat bridge and a Bronco bridge to build a 4-string tremolo.

If you look close, you can see that the string angles on the bridge are pretty bad on the A and D. I will have to take it apart and drill new string holes to correct that. But no rush, not looking forward to pulling everything apart, and drilling through the chrome is a real b!tch, it is so hard and slick. The tremolo does work, with 4 springs instead of the usual three, and the claw screwed in much further than a guitar.

Considering that it has only been together a couple of hours, and has had only the most cursory of setups, I'm pretty pleased with it. If it plays and sounds this good now, just wait after a few weeks of settling-in and a real setup.

This picture illustrates three different ways of converting a Strat to a bass, without having a scar from the tremolo hole. You can also see why converting a Telecaster body is much more difficult. In hindsight, you could mount a 24 fret neck on a stock Tele body, but you'd still have to convert the bridge. The Mustang bridge trick might also work, if you can find one.