Fret Leveling

Fret leveling begins with proper installation. First, make sure the fretboard is straight and even. A long radius sanding block is useful. Short ones may only make the problem worse.

However, you install the frets, make sure they are fully seated. I use a fret press, and then follow it up with a hammer. When all the frets are in nice and tight, start checking with a fret rocker.

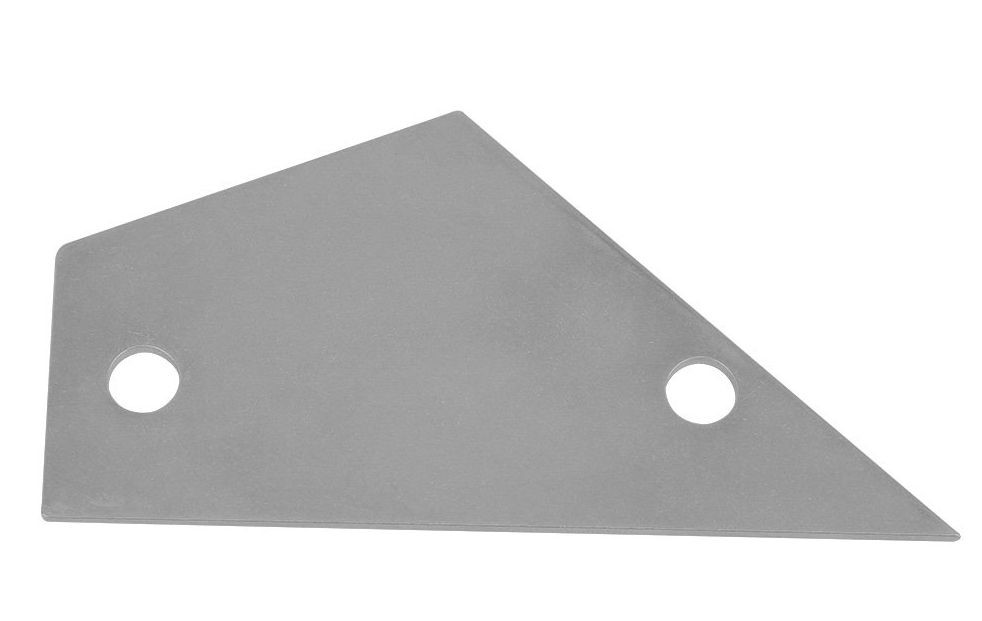

You can get one of these for under $10 on eBay, or $30 at StewMac. Aluminum works fine and is softer than fret wire, so it can't ding them.

I start at the high end and work my way down to the headstock. "Rock" the frets at each string location. Try to tap down any high spots with your fretting hammer. Only when that doesn't work, resort to filing.

When filing frets, I use a 6-inch fine file, and work it gently over the top of the high fret first. When it is almost there, switch directions and go gently up and down the neck. You can switch from a file to a sharpening stone for very fine adjustments.

Once the frets are all level, the easiest way to round over the flat tops is to wrap a piece of 400 grit sandpaper around your finger and run it up and down the neck. Follow with 1000 for a polish, then clean the wood, and you're done. Or you can get an expensive fret-crowning file, and do it the hard way.

Questions or Inquiries?

Just want to say Hello? Sign the .