Strat Tremolo Stabilizer

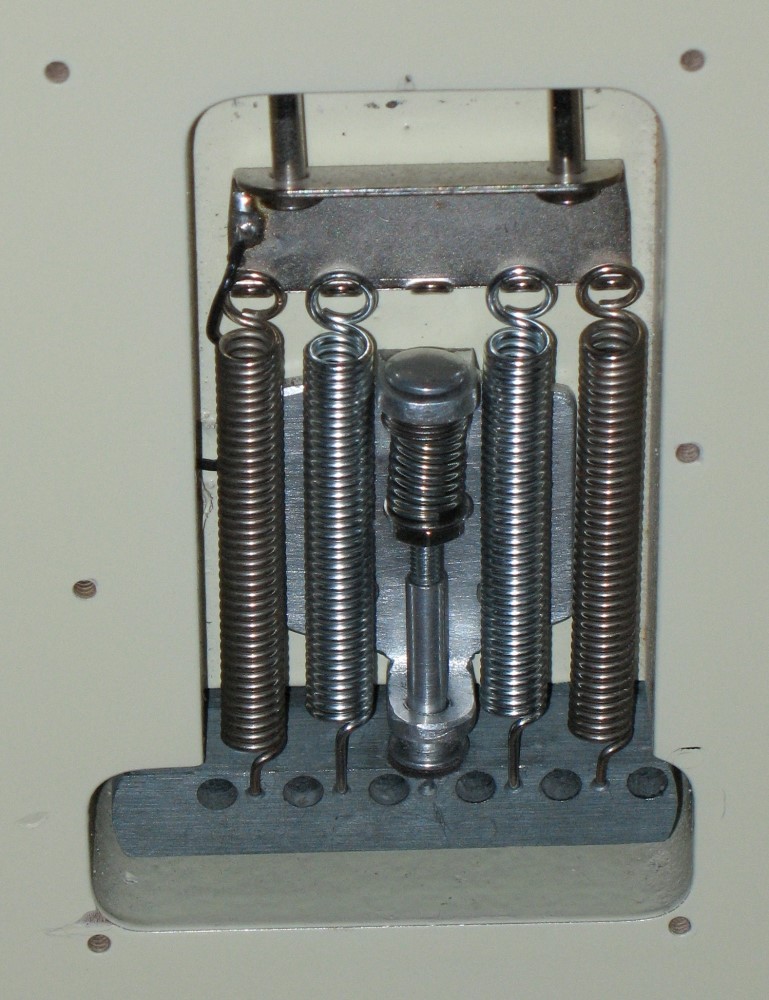

This is a Stratocaster tremolo stabilizer I built. It is functionally identical to any of those pictured below:

All of these are equivalent. They use a pre-compressed spring to hold the plunger lightly in place against the tremolo block. This gives the tremolo a resting position to return to.

The heart of the design is the plunger. For the plunger, I used a binding post from Lowes. This gives the length adjustment and the spring mounting. An additional nut and washer provide the spring adjustment. The base plate is bent-up from 1/8" aluminum. I put a hard felt button on the end of the plunger so the contact with the tremolo does not click.

This works like a charm. You can barely feel that it is there, and the tremolo returns to pitch perfectly even after the most excessive wanging and dive-bombing. Installation is trivial - a couple of short screws, all hidden.

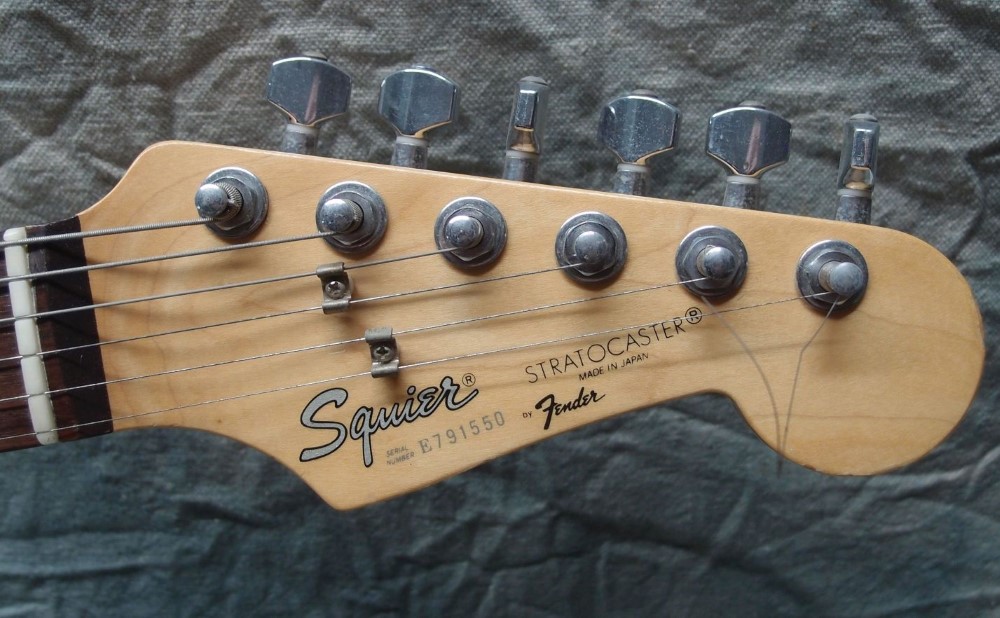

These are commonly available outside the U.S. ( where do you think I got the picture? ) But in the U.S. the guy who invented it sold the patent to Gibson. Gibson promptly deep-sixed the whole thing as a favor to Fender. One of these should be on every single Stratocaster, but instead, they are illegal.

Well, not completely. You can build your own for about two dollars, or order one from overseas for a lot more than that. StewMac sells a contraption that is functionally the same, but different enough to skirt Gibson's patent. It is a real Rube Goldberg contraption requiring some difficult and risky drilling in the guitar.

Questions or Inquiries?

Just want to say Hello? Sign the .